Our Business Segments

Water

We are committed to advance sustainable and innovative solutions in the water sector, drawing on extensive expertise and global best practices. Our portfolio encompasses high-performance systems for HVAC applications, Plumbing solutions and Water Treatment processes.

Industrial

We have established ourselves as a trusted partner, delivering comprehensive engineered flow solutions designed to support the demands of modern manufacturing and process industries.

Digital Infrastructure

We recognize the critical role that digital infrastructure plays in today’s rapidly evolving landscape.

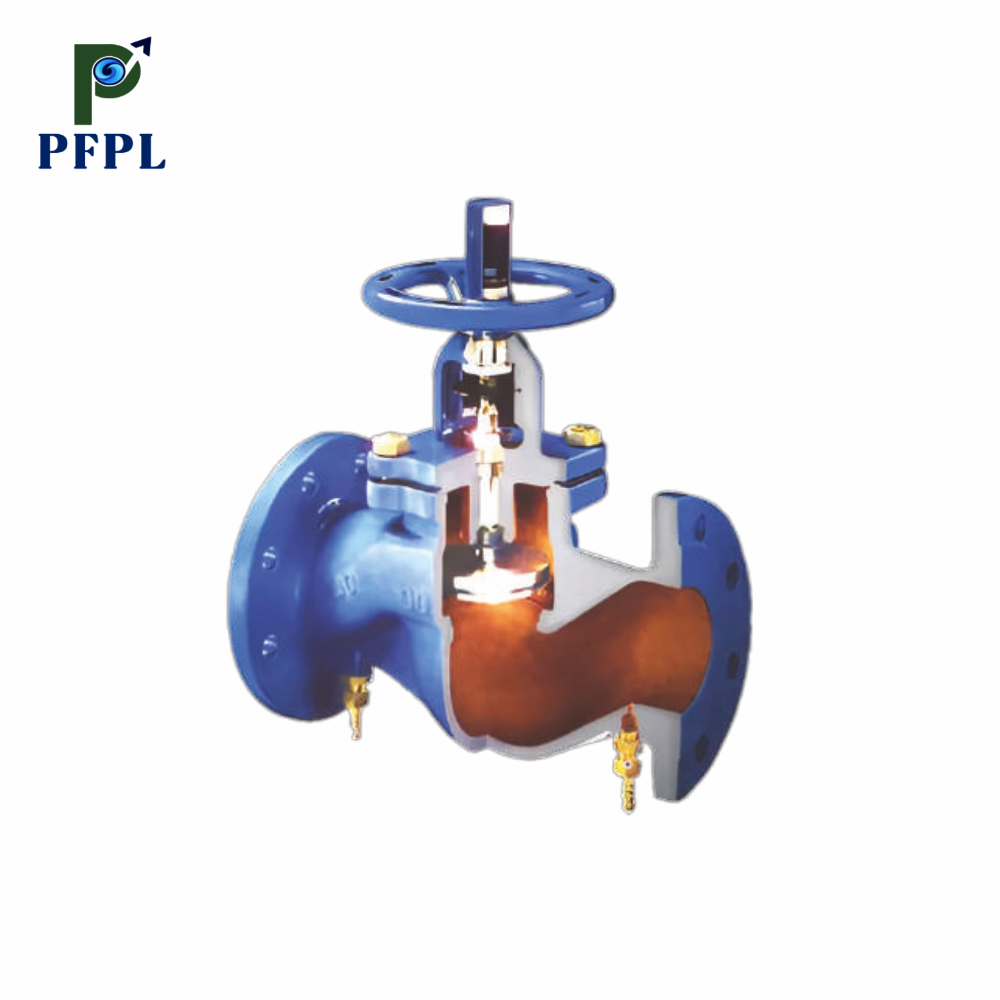

Our Products

Explore our premium product range

What we do

Empowering Industries with Intelligent Flow Solutions.

Pragati Flowtech Private Limited is a distinguished provider of engineered flow solutions with a proven track record spanning over 18 years. PFPL is dedicated to delivering high-quality and innovative water management and flow control solutions across a wide range of industries. We specialize in HVAC applications, Plumbing systems, Water Treatment consistently offering reliable and customized products and services to meet the unique requirements of each client. Our approach combines technical excellence with a deep commitment to sustainability, ensuring that every solution we provide contributes to a cleaner, more efficient future.

Our Values

What we value most

Innovation

We embrace innovation as the driving force behind our continued success. By fostering a culture of creativity and continuous improvement, we constantly explore and integrate cutting-edge technologies and processes.

Integrity

We uphold the highest standards of integrity, conducting our operations with honesty and transparency. Maintain trust in every interaction we build strong, reliable relationships with our clients, partners and stakeholders.

Commitment

We are dedicated to achieving excellence in every aspect of our work. Our commitment to delivering reliable, high-quality solutions ensures that we consistently exceed expectations and build long-term partnerships based on trust and shared success.

Global Footprint

We work with the best clients

Happy Clients

Projects

Hours Of Support

Hard Workers

Features

Our Advanced Features

Stock Water Solution

Eco-Friendly Operations

20+ years of expertise

100+ Products

Dedicated Team

24/7 After-Sale Support

Contact

Reach Out for Expert Guidance on Pumps, Water Solutions & More.

Address

Pragati Flowtech Pvt Ltd 104, Panchshil The Golden Bell, Pingale Wasti, Koregaon Park Annexe, Mundhwa, Pune, Maharashtra 411036

Call Us

+919175106075

Email Us

sales@pragati-in.com

Open Hours

Monday - Friday

9:00AM - 05:00PM

© Copyright Anvation Digital Marketing LLP All Rights Reserved